Choose your language

Request A Quote

How to do when the cutting effect is not good?

Fiber laser cutting machines are indispensable in modern manufacturing. Problems such as poor cutting of certain material thicknesses, inconsistent air pressure or misalignment of the optical path can have a serious impact on productivity. Timely resolution of these issues is critical to maintaining workflow continuity and maximizing ROI.

This guide focuses on Fiber laser cutting machine common aftermarket issues - poor cutting results - and our structured solutions all help technicians efficiently identify the root cause. With parameter adjustments, nozzle optimization and systematic hardware checks, users can restore optimal performance and ensure consistent output.

For the use of a period of time, the customer feedback cutting a certain thickness of carbon steel, the Fiber laser cutting machine cutting effect is not good.

Problem cause analysis:

1. need to confirm with the customer, is only the thickness of carbon steel cutting bad, or all thickness of carbon steel are cutting bad, if only a thickness of the other thickness of the problem is no problem, then generally just need a new parameter debugging; if all the thickness of the cutting effect is not good, then need to be further analyzed:

2. for all thicknesses are cutting bad situation, basically can be excluded from the parameter causes problems, need to be from the overall level of the machine for the basic investigation, such as whether to complete the normal operation of the use and specification, whether the alarm, whether there are special conditions such as mechanical collision led to functional damage and so on.

3. if the basic checks have been completed, then we need to consider the gas problem!

Solution:

1. for just a certain thickness of the cutting abnormality, then simply change the parameters, use the appropriate nozzle, by setting the matching speed, gas type, air pressure value, focus value, to find the best cutting results and save!

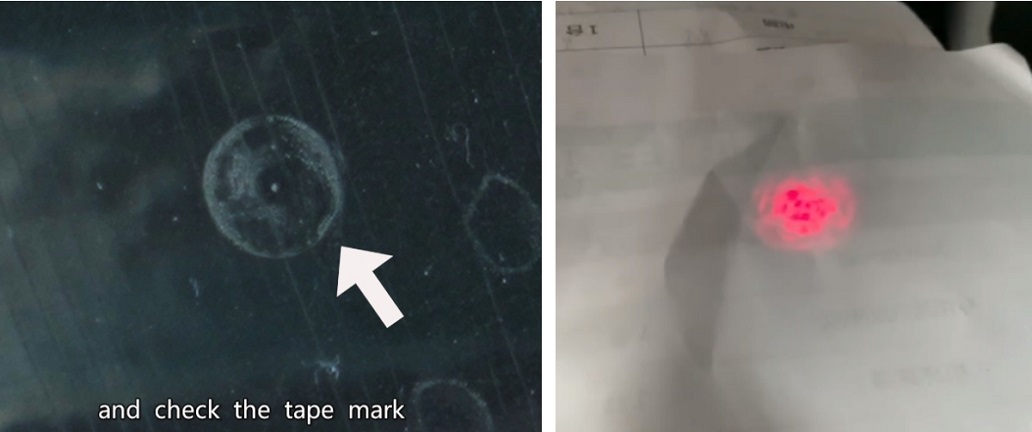

2. for all thicknesses are not cut well, you need to ask the customer about the changes in the cutting process, to find the key information, prioritize the investigation. Otherwise, you can only check all the basic items, including whether the nozzle selection is correct, whether to complete the BCS100 nozzle calibration, whether the optical path is in the center, check the state of the red light with a white paper to determine whether the laser head internal lens is clean and so on.

3. if all the daily operation of the basic project check is completed, the problem is not solved, then you need to check whether the Fiber laser cutting machine output air pressure of the oxygen meter is at 0.8MPA, and stable without leakage phenomenon; test blowing to check the oxygen proportional valve value with the setting of the blowing air pressure to match, such as mismatch, you need to test the Fiber laser cutting machine software for different air pressure settings corresponding to the value of the voltage of the actual value of the software, and then software for the correction of the pressure, or communicate with the manufacturer Communicate with the manufacturer to exclude the function of the proportional valve; if the problem is not solved, it is necessary to replace the oxygen according to the requirement that the purity of the oxygen used for cutting is more than 99.95%.